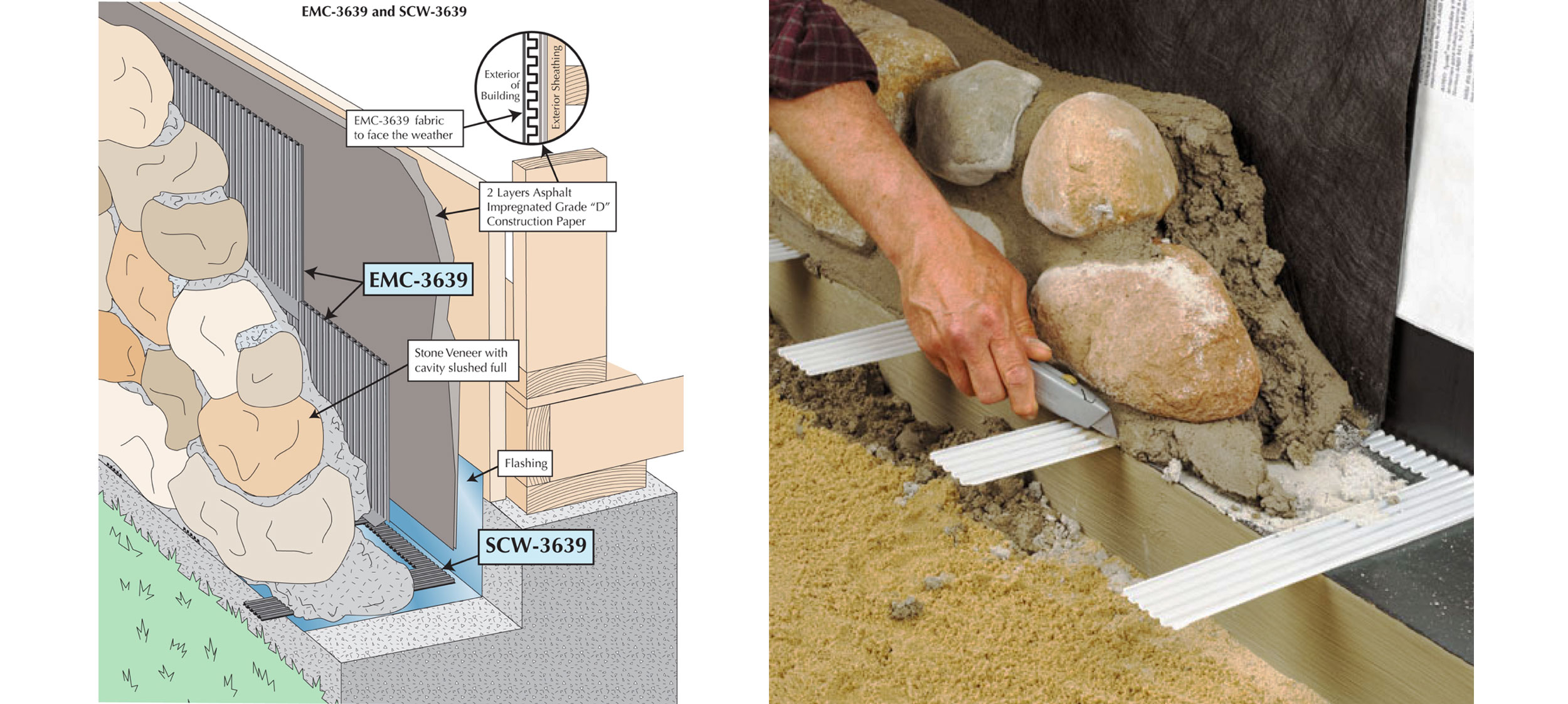

In many instances the film may be removed with sandblasting or etching with masonry detergents. If there is a chemical film on the wall, it needs to be removed. Use backer rods in caulked control joints to allow for proper joint movement during expansion and contraction.īuilding Stone Institute's recommended procedures on how to install stone veneer Caulk all joints that occur between thin stone veneer and dissimilar materials like wood, glass, vinyl, and also at all control and movement joints that occur in the structure. Apply silicone caulk to the sides of all windows and doorways. CaulkĬut paper-backed lath as close as possible around electrical outlets, and then caulk between the outlet and the lath. Flashing needs to be applied under water tables and sills, and at the base of walls where this veneer meets a brick or other ledge. It is important to follow manufacturers’ specifications for correct installations. It is important to provide a weather shield, flashing or caulk at all material transition points and at all areas that could lead to possible moisture penetration including, but not limited to, all window and door openings, electrical outlets, electrical fixtures and plumbing fixtures. Visit for further weep system information. Overlap adjoining sheets of moisture barrier at a minimum of 2” on horizontal joints and minimum 6” on vertical joints.īSI recommends including a weep system behind an exterior installation of Natural Full Veneer and Natural Thin Stone Veneer.

Moisture Control: If additional moisture control is desired, a moisture-resistant barrier can be applied to all vertical wood or moisture-sensitive backup walls. The industry organization, Building Stone Institute (BSI), recommends that a highly qualified waterproofing company/contractor handle this portion of the installation or knowledgeable masonry subcontractor adhering to industry standards. Waterproofing is an extremely important process, which must meet or exceed all local building codes.

0 kommentar(er)

0 kommentar(er)